The anti-vibration motor mounts highlighted here represent one of the many successful product lines that we manufacture here at Allstates Rubber & Tool Corporation. Characterized by the quality of their construction and attractive pricing, these motor mounts are in widespread use today at companies around the globe.

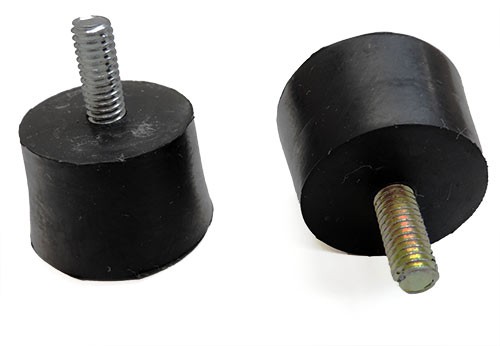

Vibration isolation is a key element to reducing the transmission of energy from vibrating equipment and machinery. Vibration causes premature wear and tear, loosens fastening hardware, and generally disrupts smooth equipment operation. Capable of sustaining high vibration frequencies, these motor mounts feature two separate bolts molded into a durable, energy-absorbing, 50 durometer Neoprene disk. Each bolt features an enlarged head and corrosion resistant, zinc-plated stem. Bolts are coated with a high-performance adhesive to promote strong, permanent bonding to the oil-resistant Neoprene.

Vibration isolation is a key element to reducing the transmission of energy from vibrating equipment and machinery. Vibration causes premature wear and tear, loosens fastening hardware, and generally disrupts smooth equipment operation. Capable of sustaining high vibration frequencies, these motor mounts feature two separate bolts molded into a durable, energy-absorbing, 50 durometer Neoprene disk. Each bolt features an enlarged head and corrosion resistant, zinc-plated stem. Bolts are coated with a high-performance adhesive to promote strong, permanent bonding to the oil-resistant Neoprene.

Manufactured using a compression molding process, which provides a good surface finish and wastes relatively little material, we produce them in standard sizes of ¾” in height x 1.0”, 1.5”, and 2.0” in diameter. Designed to produce zero-defect product, our molds undergo regular inspection and maintenance to ensure the highest degree of quality on every production run. Our custom-developed assembly line is engineered to uniformly apply the bonding agent and insert the bolts with repeatable precision.

To suit the needs of individual applications, we customize these mounts with different insert thread sizes. We also tool the mold to accommodate larger or smaller bolt sizes as needed. This has proven to be a very cost effective option when compared to a custom-tooled solution, and one that many of our clients take advantage of on a regular basis.

If you are interested in learning more about this product or any of our manufacturing processes, contact us today.